Boost Converters

I have used two boost converter ICs in my IoT Nodes. The Aerosemi Technology MT3608 seems to be the most commonly used in boost converter modules available though AliExpress and is capable of providing the 24V output that I needed for one of my sensors. In situations that only require a 5V supply less than 800mA, I have used the Feeling Technology FP6277, for which I found a much tighter packaging option. I have also recently seen the Suosemi SX1308 on AliExpress in a reltively small package that is still claimed to support output voltages up to 28V and 2A, so it might also be worth exploring as a future option.

MT3608

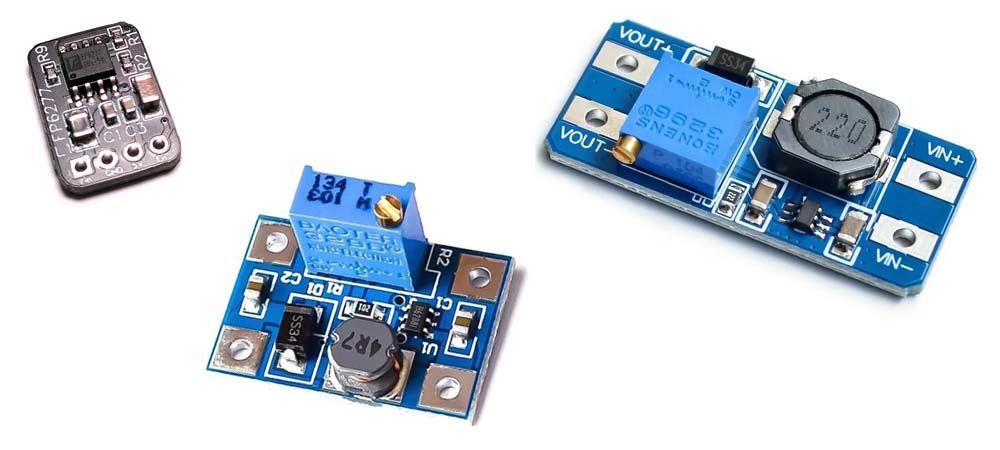

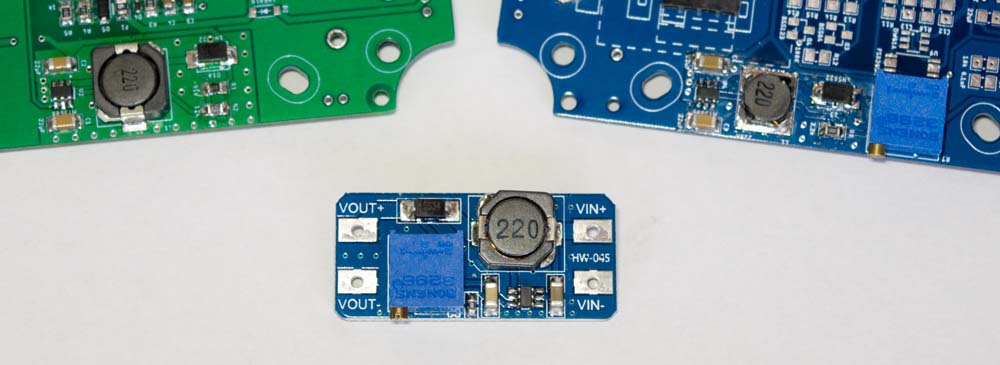

The boost converter configuration included on several base boards (e.g. 10068-BPS, at left in the above photo, and 10068-BCS-A4a, at right) is a direct copy of the circuitry on several commercially available boost converter modules (e.g. that at bottom in the above photo). This configuration can boost the voltage supplied by a [3.7V] Li-Ion battery up to ~28V, depending on the relevant resistor configuration. The commercial modules, and my general configuration, e.g. that used on the 10068-BCS-A4a board, include a trim pot to allow the output voltage to be tuned within this range to that required by any given application.

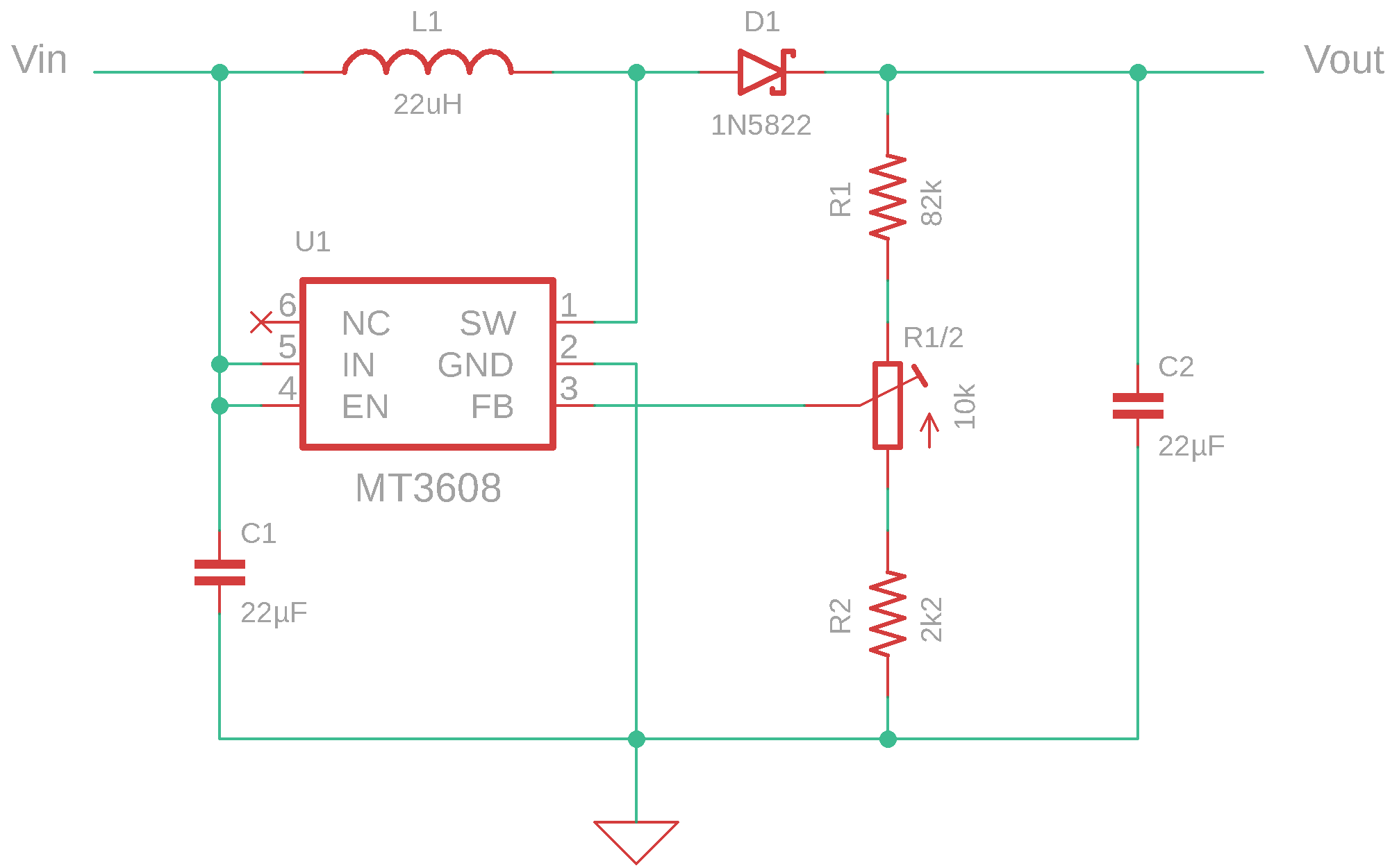

I have subsequently modified the circuit slightly by adding an extra resistor to the output circuit to provide more sensitivity in setting voltage levels. The original configuration, as per the commercially available module, used a 100kΩ trimpot, but only about 20% of its range was useful. By inserting the additional resistor and using a 10kΩ trimpot, most of the range of the trimpot can be used, allowing the output voltage to be set more precisely.

Circuit Layout

As discussed elsewhere on this site, the specific components used, and their layout, in a boost converter circuit can be a little fussy. Apart from the need to observe the guidelines provided in the relevant datasheet, in my applications care needed to be taken in choosing the physical size of some components. It may have been immediately obvious to someone with more experience in such matters, but I ultimately discovered that the physical size, not just the rating, of the inductor and output capacitor had an impact on the maximum current that could be delivered through the boost converter circuit.

In my initial attempts to keep the layout as compact as possible, I just arranged what I thought were appropriately rated components neatly on the relevant PCB. Unfortunately, these early configurations were quite unstable and never delivered the expected 24V output. When I paid more attention to the layout guidance provided in the MT3608 datasheet the results were more positive.

I encountered another problem when developing the 10068-BPS battery board to support a Raspberry Pi Zero. Once again to save space, I had used a smaller [CDRH6D28] inductor and [0805] output circuit capacitor only to discover that, while the voltage level was fine, this configuration could not deliver the required current. Using the same sized [CDRH104R] inductor and [1206] capacitor as the commercially available module, which I had successfully used to test the capability before designing my own PCB, solved this problem.

I also fried a Raspberry Pi Zero early on with an incorrectly set trim pot so, for that particular application, the green board at left in the photo above, I dispensed with the trim pot and just used a fixed resistor configuration to deliver the required 5V.

Output Voltage

From the MT3608 datasheet, the output voltage is determined by the values of the resistors in the output side of the boost converter circuit, according to the following equation:

| Vout | = | Vref × | ( | 1 + | R1 R2 | ) |

where the internal reference voltage Vref is typically 0.6V and the values of R1 and R2 are determined, in our case, by the values of resistors R1 and R2 and the setting of the trimpot R1/2.

Boost Converter Circuit

The MT3608 IC operates on an input voltage in the range 2 – 24V and generates an output voltage up to 28V.

The following table lists the theoretical output voltage across the range of the 10kΩ trimpot.

Theoretical Vout Values

| R1 | R2 | Vout (V) | ||

|---|---|---|---|---|

| R1 (kΩ) | Trimpot (kΩ) | R2 (kΩ) | ||

| 82 | 10 | 0 | 2.2 | 28.4 |

| 9 | 1 | 19.5 | ||

| 8 | 2 | 14.9 | ||

| 7 | 3 | 12.0 | ||

| 6 | 4 | 10.1 | ||

| 5 | 5 | 8.7 | ||

| 4 | 6 | 7.6 | ||

| 3 | 7 | 6.8 | ||

| 2 | 8 | 6.1 | ||

| 1 | 9 | 5.6 | ||

| 0 | 10 | 5.1 | ||

See also the specific details provided under PCB Assembly elsewhere on this site.

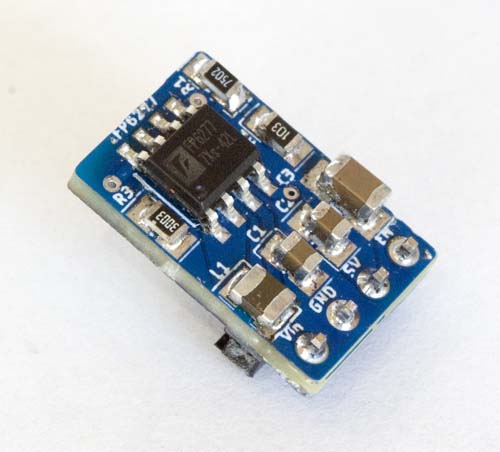

FP6277

More recently I have used a version of the compact module designed by Gerrit Niezen as a solution that can simply be plugged into a Node if and when required (see here for PCB CAD and CAM files). In particular, the Niezen design uses a chip inductor that is much smaller than than the more common and larger wire wound items.

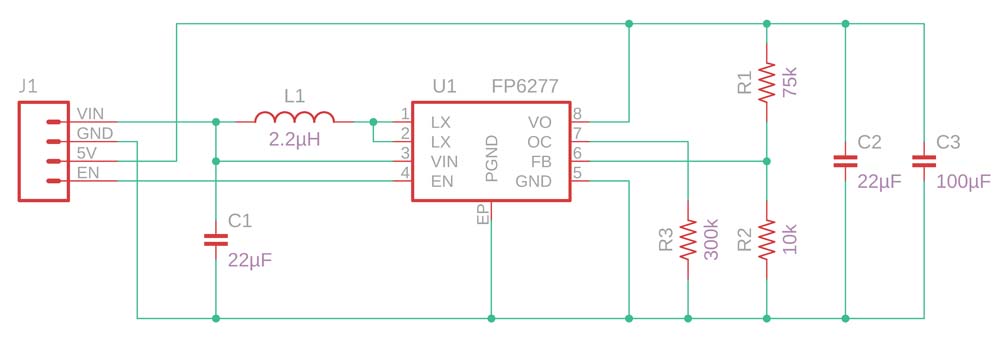

FP6277 Boost Converter Module Circuit

The FP6277 IC operatres on an input voltage in the range 2.4 – 4.5V and generates an output voltage up to 5.3V with a current limit of 800mA in the present configuration. The current limit for the FP6277 is set via the resistance configured on the OC pin and, once again, the output voltage is set according to the values of the resistive voltage divider connected to the FB pin of the IC:

| Vout | = | 0.6 × | ( | 1 + | R1 R2 | ) |

Assembly

One critical requirement that I encountered with the FP6277 was that the ground pad on the bottom of the IC must be soldered to the ground plane of the PCB—it's not enough for it to just be in contact with the pad on the PCB. Given the small size of the PCB and component involved, this turned out to be relatively straightforward process using solder paste and the heat gun on a small rework station to apply the necessary heat from the bottom of the PCB. Nonetheless, this is a complication that does not exist with either the MT3608 or SX1308 ICs.